In Northern Virginia, DC and Maryland, the Dirt Connections Construction Team has been installing new concrete driveways for years. We bring experience for all projects. From the smallest residential patio to the largest commercial hardscape package, we get the job done right. Our team offers high quality of workmanship delivered in a prompt, precise professional manner.

New Concrete Driveway Process

- Visit the site.

- Contact Ms. Utility.

- Mobilize to the site.

- Remove existing failed driveway.

- Grade to uniform depth and compact area.

- Lay woven geotextile fabric (reduces chance for material sinkage).

- Install 6 x 6 #10 wire mesh.

- Arrange new 4 inch thick 4000 PSI strength concrete.

- Place concrete material and bull float the concrete.

- Install control and expansion joints where and if necessary.

- Install a light broom finish.

- Apply seed and straw.

- Pick up and haul away all project debris.

New Concrete Driveway By The Dirt Connections Team

Five Concrete Components

- Cement

- Water

- Coarse Aggregates

- Fine Aggregates

- Air

Concrete Mix Design

Traditional concrete ingredients are made of water, cement, air, and an aggregate mixture of sand, gravel, and stone. Different proportions of these ingredients will result in different concrete strengths.

Cracks In Concrete

It is common knowledge in the concrete industry, concrete cracks. All you can do with concrete cracking is control the event.

Different Types Concrete Sealers

- Penetrating Sealers penetrating silicone sealer for your concrete. It protects concrete from salts, freeze/thaw, chemicals and other elements, featuring a combination of deep penetrating silane and surface-protecting siloxane barriers.

- Film-Forming Sealers include acrylics, epoxies, and urethanes that form a coating on the surface of the concrete. This type of sealer is sometimes referred to as a topical concrete sealer or a coating.

- Acrylic Concrete Sealer work by forming a protective film atop the concrete. The film protects the concrete in much the same way that a raincoat protects its wearer. The sealer simply covers the concrete surface with a water resistant barrier.

- Polyurethane Concrete Sealers are nearly twice as thick as an acrylic sealer and form a high-build protective film on the concrete surface that provides excellent resistance to abrasion and chemicals.

- Clear Concrete Sealers offer a clear, concrete cure & seal formulated with pure acrylic resins. Usually a non-yellowing and is highly recommended for exterior use. This sealer can darken and highlight the color of concrete, masonry, pavers, etc., giving these materials a “wet” look.

- Stamped Concrete Sealers protect stamped concrete surfaces from abrasion and wear. The make stamped concrete easier to clean and maintain.

- Driveway Concrete Sealing will help to increase the lifespan of the concrete by protecting it from UV exposure, cracking, pitting, staining and surface wear to name a few.

Slump Test

A concrete slump test is used to determine the correct water content in a batch of concrete. “Slump” is the distance, measured in inches, the concrete settles after the slump cone is removed. If you’re working in very hot or dry conditions, or if the mold has intricate shapes, you may want a slightly wetter mix. Keep in mind that the more water in the mix, the higher the risk of cracks.

Performing a concrete slump test will help give you an idea of what the right mix should feel like.

How To Do A Concrete Slump Test

Welded Wire Mesh

Wire mesh makes concrete more durable and increases its strength.

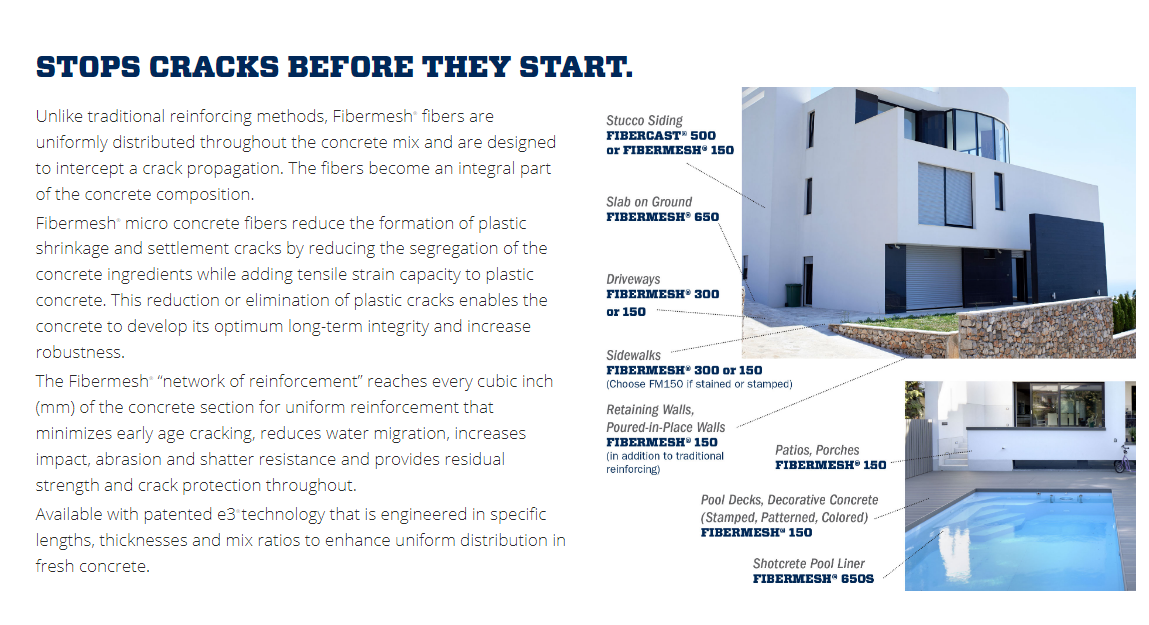

Sika Brand Fiber Mesh

Fiber mesh is made up of fibrous materials like synthetic fibers, glass fibers, natural fibers, and steel fibers. It is typically used in sidewalks, patios, and driveways.

Structural Slabs

A concrete slab is a structural feature, usually of constant thickness, that can be used as a floor or a roof.

Steel Reinforcement Bar

Rebar Sizes & Dimensions:

- #3 = approximately 7/16″ diameter

- #4 = approximately 9/16″ diameter

- #5 = approximately 11/16″ diameter

- #6 = approximately 7/8″ diameter

- #7 = approximately 1″ diameter

- #8 = approximately 1 1/8″ diameter

- #9 = approximately 1 1/4″ diameter

- #10 = approximately 1 7/16″ diameter

- #11 = approximately 1 3/8″ diameter

- #14 = approximately 1 7/8″ diameter

- #18 = approximately 2 1/2″ diameter

Woven Geotextile Stabilization Sheet

Woven geotextiles used for ground stabilization minimize rutting and prevent intermixing of the aggregate with the soft soils below. Think of woven geotextiles as affordable insurance for your aggregate. They save time and money by reducing or eliminating the need for additional rock.

Woven geotextiles are placed between the aggregate and the subgrade to stabilize the soil, preserve the aggregate and reinforce the surrounding soil.

If you are building a road, constructing a parking lot, stabilizing material staging areas or repairing/installing a gravel driveway, woven geotextiles perform at a high level and save time and money.

Bull Float Concrete

The purpose of bull floating concrete is to level ridges and fill voids left by the concrete screeding operation. Concrete screeding will embed the coarse aggregate into the concrete and raise the cementitious material to the top.

Control Joints

This joint is designed to provide concrete a place to crack.

Expansion Joints

This type of joint is completely free of mortar and often a fiberboard or polyurethane foam.

Decorative Stamped Concrete

Stamped concrete provides a decorative texture to your concrete flatwork. This decorative finish will provide additional curb appeal to your patio or driveway.

Colored Concrete

The application of colored or powdered dyes will provide different colors for concrete.

Concrete Pumping

On site, concrete pumping allows reallocation of valuable personnel to other duties and quicker placement of concrete.

Generally Speaking No Building Permit Required For Removal & Replacement Of Existing Concrete Driveways

Why Choose Dirt Connections for Your New Concrete Driveway

Selecting Dirt Connections for your new concrete driveway ensures expert craftsmanship and reliable service. Our team follows a meticulous process, from grading to the final broom finish, guaranteeing durability and a smooth surface. With years of experience serving Northern Virginia, DC, and Maryland, we use high-quality materials like 4000 PSI concrete and woven geotextile fabric to deliver a driveway that meets your needs. Trust us to enhance your property’s curb appeal and functionality with a professionally installed concrete driveway.

Concrete Delivery Companies

- Chaney Enterprises

- Vulcan

- Titan America

- Handyman Concrete

- Aggregate Industries

- DMV Concrete

- Estate Concrete

- Concrete Express

- Hard Rock Concrete

- Concrete Now

Summary

Dirt Connections was started with one goal in mind: providing quality residential and commercial construction services to clients on time and on budget. Reach out for more information on how we can support your next project.

For your convenience our estimates are free and by appointment. Call 703-940-9949 for a free estimate today!