One of the biggest determinants of a building project’s overall success is the foundation on which it is built. A lot of attention is devoted to pouring the perfect concrete slab under the ideal conditions, but it is just as important that the concrete is placed on the right base.

Subgrades And Subbases

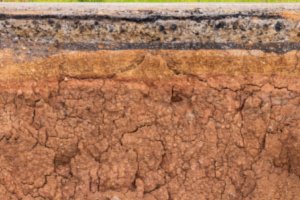

Although there is some overlap in the way that terms like subgrade and subbase are used, the American Concrete Institute defines subgrade as the native soil beneath a slab. This layer of soil is usually compacted prior to construction. In cases where the native soil is unsuitable, improved soil may be added first.

The subbase is the layer of gravel that is placed across the subgrade. This is sometimes topped by the base, or base course, which is a layer of material placed on the subbase that goes directly beneath the slab itself.

Why Is A Subgrade Important?

The subbase and base layers are not required in every project, but the subgrade is essential. After all, without a solid ground, there is nowhere to place the slab.

In places where the natural soil lends itself well to compaction and is fairly clean, the slab can be poured right on top of it without creating any additional layers.

However, if the soil has poor drainage properties or is prone to muddiness and is difficult to compact, workers may struggle to get the ground flat and achieve the required grade. In most cases, the top of the subgrade is graded to a figure of +/- 1.5 inches of the specified elevation. When this is not feasible, a subbase may be needed.

How Can Subgrade Be Improved?

Not all soil lends itself well to serving as subgrade, but compaction can go a long way toward improving it. This involves squeezing as much moisture and air out of the soil as possible so its solid soil particles are pushed together. This has the effect of making the soil denser. Soil with a higher density has a greater load-bearing capacity, and compacting soil also makes it more difficult for moisture to move through it.

Some of the benefits of compacting subgrade for concrete include:

- Preventing frost damage from occurring when the soil beneath the slab freezes;

- Reducing contraction and swelling;

- Raising the amount of weight that can be placed on the concrete; and

- Minimizing the amount of settling that will take place when the slab is poured over the soil.

When the soil is in particularly bad condition for subgrade or especially high loads will be used on it, soil stabilization may be necessary. This process involves mixing lime, calcium chloride or portland cement into the soil before compacting it. Another option is to excavate the subgrade soil, mix it with gravel, and then compact it.

When Is A Subbase Needed?

When heavy loads are expected on a slab, such as forklifts or trucks, a thick subbase is recommended. Subbase is usually made out of affordable gravel. Thicker subbases can naturally accommodate heavier loads. They can also serve as a capillary break, stopping water from being picked up from the groundwater table up into the slab.

In cases where grading proves challenging, a base course atop the subbase can facilitate grading and flattening. A choker course of fine material over the subbase can provide support during concrete placement and help the slab achieve a uniform thickness. This can save significant money on the expense of concrete.

A flat base course is also useful for reducing the risk of drying shrinkage, which is when cracks occur as concrete contracts after it has been placed. This is because a flat base course allows the slab to slide more easily as it shrinks.

Base course materials should not have silt, clay or organic materials; a granular fill that passes a No. 100 sieve is a good choice. Crushed recycled concrete aggregate and manufactured aggregate are also suitable for the base course.

In cases where subbase and base courses are used, a thickness of at least 4 inches is a good target. However, in some cases, an engineer may specify a thicker layer for better support.

Determining The Compaction Of Subgrade

A Proctor test can be used to determine how much the soil can be compacted for subgrade This entails placing soil in a cylinder and using different weights to compress it. This helps identify the relationship between moisture and soil density and can pinpoint the maximum soil density one can expect to achieve.

There are simpler ways to get a rough idea of the subgrade soil’s moisture content bearing capacity, however. For example, a ball of soil can be squeezed by hand and observed. If it does not hold a shape and is powdery, it is a reliable sign that the soil is too dry. Soil that does not break when dropped and leaves moisture on your hands is too wet. The ideal soil will mold into a ball that breaks into a few pieces when it is dropped.

Tools For Compacting Subgrade

Subgrade can be compacted using static force, which relies on the weight of the machine for compaction, or vibratory force, which uses a mechanism to vibrate soil and reduce the friction between particles so they are easier to squeeze together.

Granular soils are best compacted with vibrating plates or rollers. The lifts for sand can be around 10 inches, while those for gravel can be up to 12 inches.

For cohesive soils, a machine with a high impact force is needed to shear them. Rammers work well for smaller jobs, while padfoot rollers are ideal for medium jobs.

For major works such as highways, ride-on vibratory rollers equipped with smooth or sheepsfoot rollers are the most efficient choices for compaction.

Contact Dirt Connections To Learn More

The team of experienced contractors at Dirt Connections can help you with your next construction project. Offering a broad variety of site preparation services for works of all sizes, from dirt grading and soil compaction to foundation excavation, we can help you ensure your Northern Virginia construction project is successful.

Summary

Dirt Connections was started with one goal in mind: providing quality residential and commercial construction services to clients on time and on budget. Reach out for more information on how we can support your next project.

For your convenience our estimates are free and by appointment. Call 703-940-9949 for a free estimate today!