At the heart of any successful concrete slab job is a good subgrade. A slab is not meant to be self-supporting; it is the soil support system found below it that provides it with the foundation it needs. This means that the efforts made to prepare the ground prior to pouring concrete will have a direct effect on the integrity of the finished product.

What Is A Subgrade?

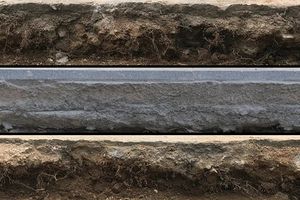

Although you may encounter the term subgrade being used interchangeably with subbase, these are actually two different parts of a soil support system. The subgrade is the native soil or improved soil below a base. It is normally compacted to provide support. The subbase is a layer of gravel that is placed atop the subgrade. This is then topped with a base or base course, which is a layer of material that rests on the subbase directly beneath the slab.

However, of the three layers mentioned, the only one that is a firm prerequisite before laying concrete is the subgrade. This must be in place and prepared properly before a concrete slab can be laid over it. If the natural soil at the site is fairly clean and compactable, it is possible to pour the slab directly over it once it has been prepared without needing any additional layers.

Preparing Subgrade For Concrete

Here is a look at the steps involved in preparing subgrade for concrete.

Clear the Area

The first step before beginning any concrete project is making sure the area is as clear as possible. After calculating the depth of the concrete project, remove all of the soil, rocks, organic materials and other items that are currently occupying the space. Take care to remove enough material to allow the final area of the concrete to sit slightly above the ground.

Backfill

Before pouring concrete, the area needs to be backfilled using gravel, crushed stone or sand. Backfilling will provide a base to facilitate an even pour, in addition to giving the concrete strength. The backfill should be leveled to a uniform depth of four inches or more.

Compact The Subgrade

Next, the subgrade must be compacted carefully. Several tools are suitable for the job, and the right one will depend on the overall size of the project and the type of soil in question.

The two main approaches are a static and vibratory force. Static force relies on the weight of the machine to compact the subgrade, while vibratory force uses some type of mechanism for vibrating the soil, which will reduce the friction that occurs between particles of soil so they can squeeze together more easily.

Here is a look at the best tools for compacting different types of soil for subgrade.

Cohesive Soils

Cohesive soils must be sheared for compaction, so a machine with a high impact force, such as a rammer, is the ideal choice; a pad-foot roller may work better for bigger jobs involving cohesive soil.

Granular Soils

In granular soils, it is sufficient to vibrate the particles to move them closer together. Rollers and vibrating plates are good choices for this type of soil.

For smaller jobs, a one-way or reversible vibratory plate compactor or rammer is suitable. Medium-sized jobs can use tools like walk-behind rollers with smooth vibrating rollers or padded rollers. For bigger jobs such as highways, larger ride-on models of vibratory rollers equipped with smooth or sheepsfoot rollers are used for compaction.

The subgrade must be uniform, hard and well-drained. If it is not compacted properly, it could lead to cracking.

Forming

Forms can be used to help create a uniform, clean concrete and determine its final grade. A slight slope of around one-eighth of an inch is recommended to prevent water from puddling on the line.

To set the grade at the surface of the slab, a string line and level should be used. The stakes should be placed in the ground at intervals of up to four feet apart in a way that allows the face of the stake to line up with the string line. A stake should also be placed at every joint.

The forms can be created with lumber and raised so that their tops are even and level with your string line. Once you are satisfied that everything is perfectly even, nail them to the stakes. It is also a good idea to brace the form for further durability as wet concrete could potentially break it.

With the forms in place, the subgrade is finished, and the concrete can be poured.

When Is A Subbase Or Base Course Needed?

However, there are some cases where a subbase and base course may be needed.

Subbase

For example, if the soil does not drain well or gets muddy easily, it may be difficult to compact, flatten and grade; the top of the subgrade generally needs to be graded to within plus or minus 1 ½ inches of the specified elevation.

A thicker sub-base can be used on subpar soils to better support higher loads. In cases where heavy loads will be passing on the slab, such as forklifts or trucks, a thicker subbase may be needed. In addition, a subbase can serve as a capillary break, stopping water from the groundwater table from wicking up into the slab.

Although it requires an extra step, it is worth noting that subbase material tends to be low-cost gravel, which means it does not add too much to the overall expense of the project.

Base Course

Laying a base course over the subbase makes it easier to create a flat and proper grade. A choker course of fine material atop the subbase can support equipment and crews while placing concrete. It can also help the slab retain a uniform thickness, which can result in cost savings on concrete.

Another benefit of using a flat base course is that it enables the slab to slide easily while shrinking, reducing the risk of developing the types of cracks that can arise after placement due to drying shrinkage.

Get In Touch With The Concrete Paving And Site Preparation Professionals

Dirt Connections is a top provider of commercial and residential concrete paving, dirt grading, site preparation and excavating services in the Northern Virginia area. Get in touch today to find out how their experts can do all the heavy lifting on your next project.

Summary

Dirt Connections was started with one goal in mind: providing quality residential and commercial construction services to clients on time and on budget. Reach out for more information on how we can support your next project.

For your convenience our estimates are free and by appointment. Call 703-940-9949 for a free estimate today!