With your new project, you have to dig some new footing. Your new footing excavation will require an enhanced skill set to get this work done. Let’s go over how I can help you get this work done.

With your new project, you have to dig some new footing. Your new footing excavation will require an enhanced skill set to get this work done. Let’s go over how I can help you get this work done.

Plans

Know your plans. You must know how to read the project plans.

As for the plans you need to decipher the width, depth and length of the footings you must dig. Proper footing placement is a must for the successful completion of your project.

Contact Ms. Utility

Before You Dig, Contact Ms. Utility. Get Your Work Area Marked For Underground Utilities. This Is A Must.

Site Prep

Now work the work and project area defined, make sure to clear the site of all obstructions. Remove all timbers, rocks, plants and any and all items that will interfere with your excavation. After the clearing of obstructions, level the area (if possible) for a level ground. The level ground will improve your work efficiency and footing work.

A clean and clear project site will make your life easier. Be sure to consolidate all debris to an area that will not impede your new footing excavation.

When you dig a footing you will generate dirt and spoils. You need to be aware of the placement and future removal of the spoils. If you can lose this spoils on site, this often results in cost savings (no dump truck loading and haul off).

Site Layout

After reading and understanding the plans, you must transfer the footing layout to the ground. This will require some help. I suggest you have the following tools:

- String Line

- Paint

- Tape Measure

- Helper

- Patience

- Understanding

- Wood or Steel Stakes

- Plans in Hand

With the layout staked out with paint and or stakes, you are ready to get started digging.

Planning

Before you start digging, you want to have a plan. You want to start at the location that avoids going over the new footing excavation work you have completed. Driving over your work, often ruins the footing dig. This happens when dirt falls into the work you have completed.

Digging

When it comes to digging the footing, I like to paint the outside edge of the footing. As I move back, the outside edge helps me to visualize the new work that is to be completed.

Bucket Size

The bucket size is very important, that’s why knowing and understanding your plans is so important. You want to be sure you get the appropriate bucket width. If you have a 16 inch wide footing, get a 16 inch wide bucket or the closest size available. If it’s a 24 inch wide footing, get a 24 inch wide bucket. When you excavate your new footing, you want to make one pass with the bucket. This is super important for all novices. Experienced professionals can work magic, however they always prefer the appropriate bucket width for the new footing excavation.

Tricks of the Trade

The correct width of the bucket needs to coincide with footing width, as per plan.

The depth can be eyeballed if you know the length of the bucket from the teeth to the back. This can be approximately 24 – 30 inches. You can use this value to guesstimate the depth of your footing with the grade and the known length of the excavator bucket.

Straight lines for footings can be maintained when you use the excavator tracks of mounting arms of the plow blade (not on all excavator models).

Spoils & Consolidation

After generating the spoils, you want to place them where they do not obstruct the concrete crew. Either you can back grade and level or move them to another location on the job site. You want the concrete crews to have access to your footing. Here the concrete crews need room, to hand finish the footing dig, install the steel reinforcement bars and grade pegs and place the concrete.

Haul Off

When it comes to dirt spoils haul off, you want to have this material consolidated for quick loading. You want to make sure you can get the dump trucks close to the consolidated material for quick and safe loading. The faster you load, the more money you will save.

Again, think about the dump truck drivers, make sure the loading area is level, firm and safe.

Clean Up

I love a clean job site.

If you do have debris and spoils, segregate the materials. If appropriate, cover the materials. A tidy job site reflects well for all the involved parties.

Equipment Maintenance

Fuel

Fill up at the end of the day.

Grease

Provide grease to all fittings – everyday.

Hydraulic Fluid

Always check the hydraulic fluid.

Oil

Check the oil daily.

Finished with Machine

Park Safely & Out Of The Way

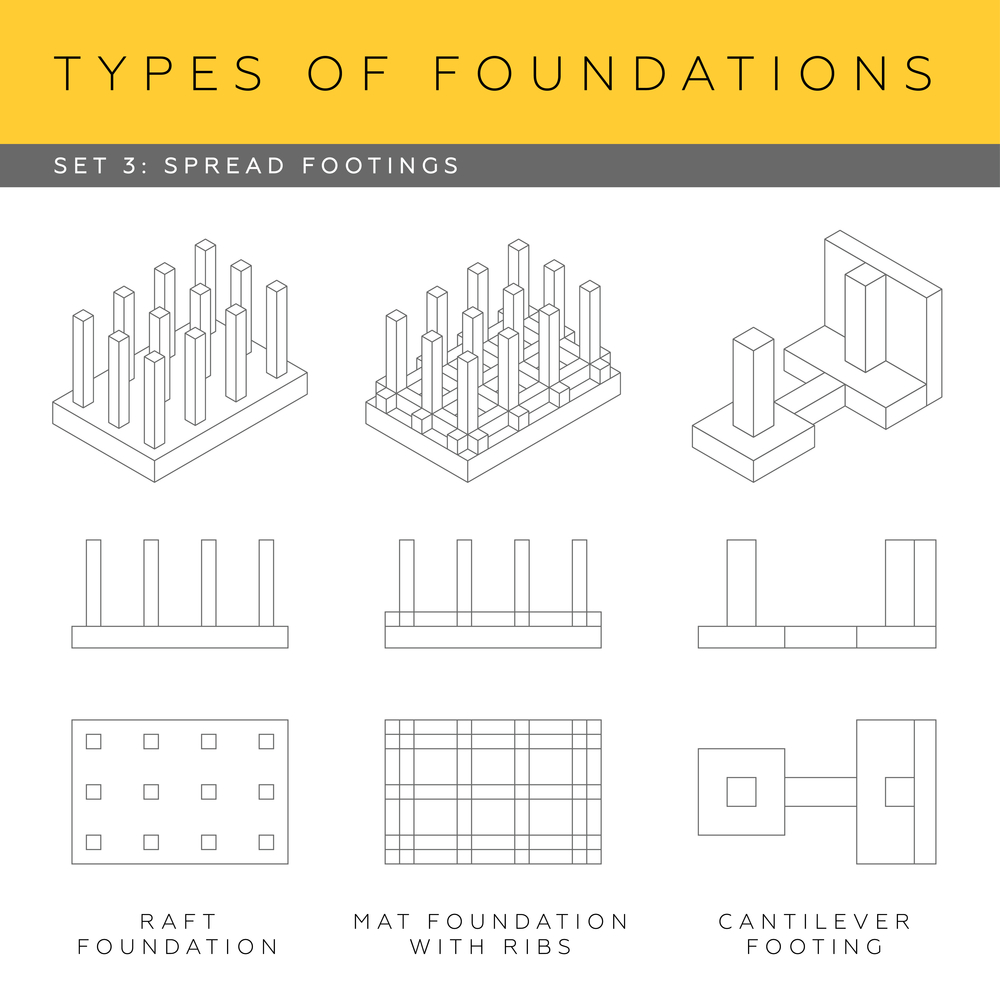

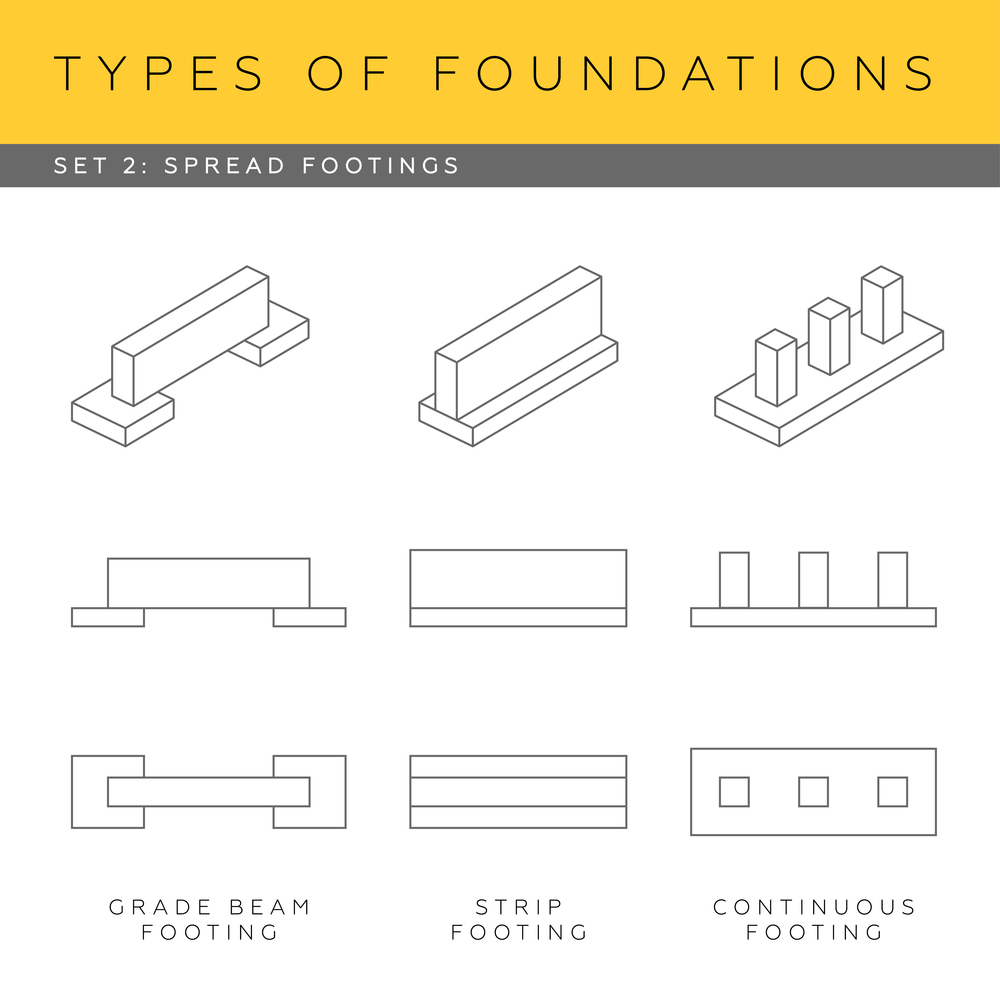

Types of Footings

Consider Footing Types for Your Project

Understanding the different types of footings is crucial for the success of your excavation work. Whether you’re digging for strip footings, isolated footings, or combined footings, each requires careful planning and execution. Strip footings are typically used for load-bearing walls, while isolated footings support individual columns. Combined footings are used when columns are closely spaced. Knowing the specific type of footing you need will ensure that the excavation process is tailored to your project’s requirements, leading to a stronger foundation and smoother construction process.

Summary

Dirt Connections was started with one goal in mind: providing quality residential and commercial construction services to clients on time and on budget. Reach out for more information on how we can support your next project.

For your convenience our estimates are free and by appointment. Call 703-940-9949 for a free estimate today!